| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Ruixiang |

| Model Number : | RX-15HP |

| Certification : | ISO9001/CE |

| Price : | RMB 6500-800000/PC |

| Payment Terms : | T/T |

| Supply Ability : | 30 units per month |

| Delivery Time : | 30 days |

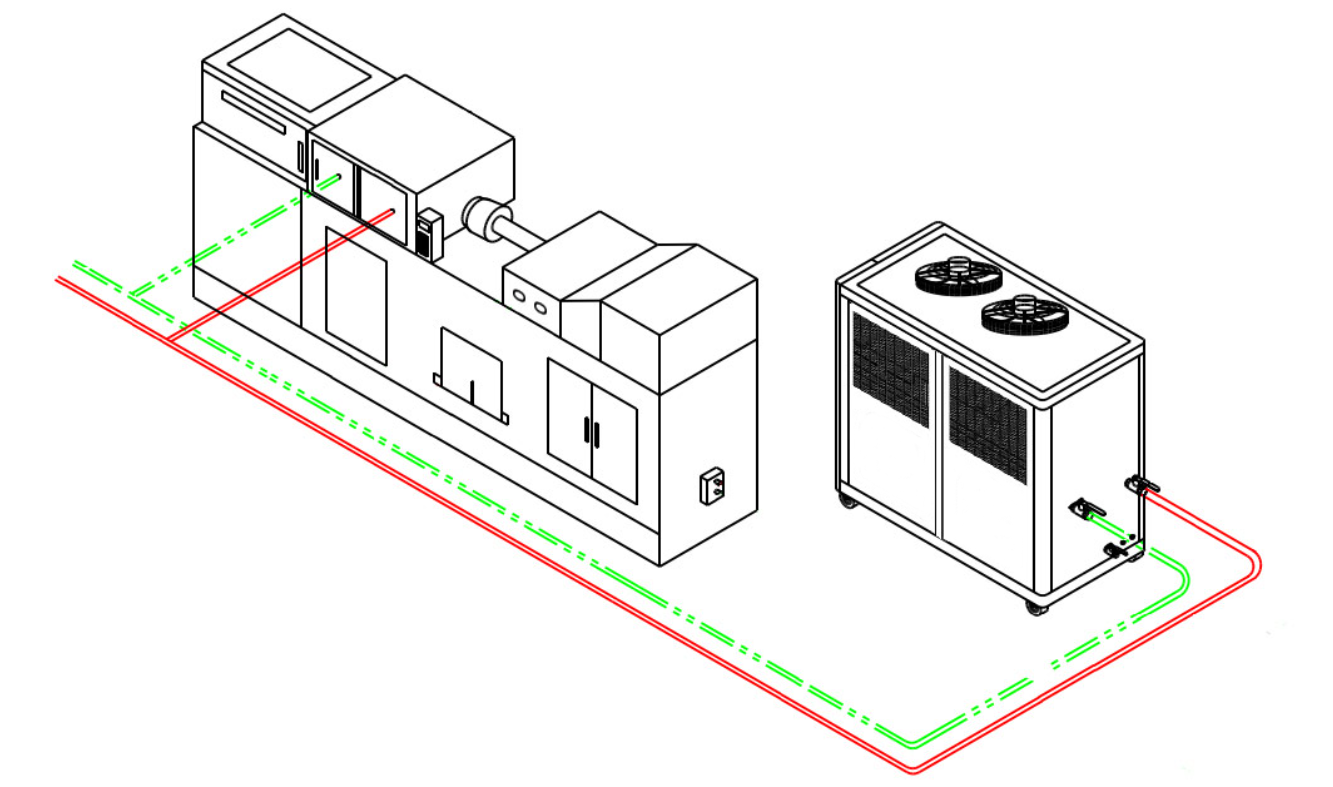

Low Carbon Technology Of Chemical Chillers Reshapes The Industrial Cooling Ecosystem

Chemical chillers are refrigeration equipment designed specifically

for complex working conditions in the chemical industry. They can

provide stable and accurate low-temperature cooling media for

various reactors, condensers, heat exchangers and other equipment

in the chemical production process. By controlling the process

temperature, they ensure that chemical reactions are carried out

under safe and efficient conditions, avoiding product quality

degradation, equipment damage and even safety accidents due to

abnormal temperature.

Product Features:

Chemical chillerhave the following characteristics:

1.High efficiency and energy saving: The industrial air cooler adopts high-efficiency and energy-saving compressors and coolers, which have high cooling efficiency and can save energy.

2.Flexible installation: The industrial air cooler can be installed indoors or outdoors, and the type selection and installation can be carried out according to specific needs.

3.Simple maintenance: The maintenance of industrial air coolers is relatively simple, and only requires regular cleaning and maintenance, which is relatively easy to maintain.

4.Long service life: The main components of the industrial air cooler have a long service life, which can ensure the stable operation of the equipment.

5.High temperature control accuracy: TheChemical chiller is equipped with a precise temperature control system, which can achieve precise temperature control.

Techinical Parameters:

| Model | RX-3HP | RX-5HP | RX-8HP | RX-10HP | JLSLF-12HP | RX-15HP | RX-20HP | RX-25HP | RX-30HP | RX-40HP | ||

| Cooling capacity | KW/h | 8.85 | 14.75 | 23.6 | 29.5 | 35.4 | 44.25 | 59 | 73.75 | 88.5 | 118 | |

| Kcal/h | 24,338 | 40,563 | 64,900 | 81,125 | 97,350 | 121,688 | 162,250 | 202,813 | 243,375 | 324,500 | ||

| Temperature range | 3℃~35℃ | |||||||||||

| Power supply | 1N-220V 50HZ/60HZ 3N-380V/415V 50HZ/60HZ | |||||||||||

| Total power | KW | 2.57 | 4.31 | 7.65 | 9.9 | 11.4 | 13.7 | 18.8 | 22.59 | 27.1 | 36.1 | |

| Compressor | Type | Hermetic scroll type or piston | ||||||||||

| Power | KW | 2.25 | 3.75 | 6 | 7.5 | 9 | 11.25 | 15 | 18.75 | 22.5 | 30 | |

| Refrigerant | Type | R22/R407c/R134a/R410a | ||||||||||

| Control method | Temperature Sensing External Pressure Equalizing Expansion Valve | |||||||||||

| volume | Kg | 1.8 | 3 | 4.8 | 6 | 7.2 | 9 | 12 | 15 | 18 | 24 | |

| Cooling wind | m³/h | 370 | 800 | 1560 | 2300 | 2750 | 3360 | 4100 | 4800 | 5400 | 6200 | |

| Cold wind pressure | Pa | 340 | 520 | 780 | 890 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| Fan power | KW | 0.35 | 0.5 | 0.75 | 1.5 | 1.8 | 2.2 | 3 | 3.75 | 4.5 | 6 | |

| Cooling air volume | m³/h | 3000 | 5000 | 8000 | 10000 | 12000 | 15000 | 20000 | 25000 | 30000 | 40000 | |

| Blower power | KW | 0.28 | 0.36 | 0.6 | 0.75 | 0.9 | 1.2 | 1.2 | 1.6 | 2.4 | 3.6 | |

| Outlet pipe diameter | mm | 100 | 125 | 150 | 150 | 150 | 150 | 200 | 200 | 250 | 300 | |

| Machine size | L | mm | 800 | 1100 | 1330 | 1330 | 1330 | 1550 | 1760 | 1970 | 2000 | 2100 |

| W | mm | 600 | 700 | 750 | 750 | 750 | 780 | 860 | 900 | 1130 | 1400 | |

| H | mm | 1190 | 1240 | 1330 | 1330 | 1330 | 1460 | 1560 | 1700 | 1660 | 1750 | |

| Unit weight | Kg | 150 | 260 | 360 | 420 | 460 | 530 | 600 | 700 | 820 | 950 | |

Application Industry:

Chemical chiller are used in the following industries and occasions:

1. Chemical synthesis reaction: In chemical synthesis, many

reactions are sensitive to temperature. For example, in organic

synthesis reactions, the chiller absorbs the reaction heat through

circulating cooling water, controls the temperature fluctuation in

the reactor within a very small range, ensures that the reaction is

carried out at an appropriate temperature, and improves the

reaction selectivity and yield. For exothermic reactions such as

polymerization reactions, precise temperature control can avoid

overheating of the reaction, resulting in product deterioration,

equipment damage, and even safety accidents.

2. Material cooling and crystallization: During the crystallization

process of chemical products, the chiller provides a stable

low-temperature environment, allowing the material to gradually

crystallize at a suitable temperature, which helps to obtain

products with uniform particles and high purity. For products such

as fine chemical intermediates that require rapid cooling and

crystallization, the chiller can meet their rapid cooling

requirements and shorten the production cycle.

3. Storage and transportation: Some chemical raw materials and

products need to be stored and transported in a low-temperature

environment to prevent deterioration, volatilization, or dangerous

reactions. The chiller can provide precise low-temperature cooling

for storage tanks and transport containers to ensure material

quality and safety.

Automotive Manufacturing Chemical Engineering Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic Packaging Industry Printing Industry

Upport and Services:

Chemical chiller technical support and service includes:

1. 24/7 customer support

2. Remote guidance installation and maintenance

3. Remote Diagnostics and Troubleshooting

4. Phone/Email Advice and Guidance

5. User friendly documentation and manuals

6. Software Updates and Upgrades

7. Cost price of spare parts and consumablesPacking and Shipping:

How does the chemical chiller control system work?

1. Temperature monitoring: Install a temperature sensor on the

outlet pipe of the chiller or the equipment that needs to be

cooled, and its function is to monitor the water temperature in

real time.

2. Feedback and adjustment: The temperature sensor transmits the

monitored water temperature signal to the controller, and the

controller compares the actual water temperature with the set

constant temperature value. When the actual water temperature is

higher than the set value, the controller will increase the cooling

capacity of the refrigeration system, such as increasing the speed

of the compressor to allow more refrigerant to participate in the

circulation and enhance the cooling effect, or increase the opening

of the throttle valve to allow more refrigerant to flow into the

evaporator to absorb heat; if the actual water temperature is lower

than the set value, the controller will reduce the cooling

capacity, such as reducing the compressor speed or reducing the

throttle valve opening, so as to ensure that the water temperature

always remains within the set constant temperature range.

4. Protection function: The control system also has a variety of

protection functions. For example, the pressure of the

refrigeration system is monitored by the pressure protection

device. When the pressure is too high or too low, it will

automatically shut down and sound an alarm to prevent the equipment

from being damaged due to abnormal pressure. Overload protection is

set. When the compressor, water pump and other equipment are

overloaded, the power supply is automatically cut off to avoid

equipment burning. There is also liquid level protection to monitor

the liquid level of refrigerant or cooling water. When the liquid

level is too low, an alarm will be sounded and the machine will

shut down to prevent the refrigeration effect from being affected

or the equipment from being damaged due to insufficient liquid

level.

|