| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | Xruixiang |

| Model Number : | RX-20AD |

| Certification : | ISO9001/CE |

| Price : | RMB 6500-800000/PC |

| Payment Terms : | T/T |

| Supply Ability : | 500days |

| Delivery Time : | 15-20 Units |

10 Ton Water Cooled Explosion Proof Screw Chiller

Product Description:

The air-cooled explosion-proof chiller is an explosion-proof chiller with the characteristics of explosion-proof design, air cooling, environmental protection and energy saving, high-efficiency performance and convenient installation. It is suitable for places requiring explosion-proof measures, such as chemical industry, petroleum, natural gas, medicine and other fields .

Production Features:

The main features of the air-cooled explosion-proof chiller include:

1. Explosion-proof design: The air-cooled explosion-proof chiller adopts an explosion-proof design, which can operate safely in flammable and explosive places to ensure production safety.

2. Air cooling: The air-cooled explosion-proof chiller adopts air cooling method and does not require water source, which reduces water consumption and discharge, and also reduces the cost of water treatment.

3. Environmental protection and energy saving: The air-cooled explosion-proof chiller uses environmentally friendly refrigerants and an efficient refrigeration system, which can reduce the impact on the environment and reduce energy consumption while ensuring the cooling effect.

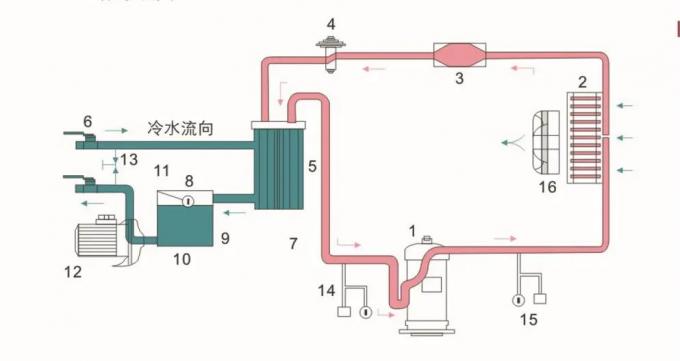

Working Principle:

The air-cooled explosion-proof chiller mainly realizes refrigeration through a refrigeration system composed of a compressor, a

condenser, an evaporator and a fan. It works as follows:

1. The compressor compresses the low-temperature and low-pressure refrigerant gas into a high-temperature and high-pressure gas, which is then sent to the condenser.

2. The refrigerant gas in the condenser is cooled and condensed into a high-pressure liquid by exchanging heat with the outside air.

3. The high-pressure liquid is decompressed through the expansion valve, becomes a low-temperature low-pressure liquid, and then enters the evaporator.

4. The refrigerant liquid in the evaporator exchanges heat with the outside air, thereby absorbing the heat in the air, and evaporating the refrigerant liquid into a low-temperature and low-pressure gas.

5. The low-temperature and low-pressure gas enters the compressor to start a new refrigeration cycle.

At the same time, the air-cooled explosion-proof chiller also introduces air into the condenser and evaporator through the fan for cooling and heat exchange. Due to the air cooling method, no water source is required, and it is suitable for places where no water source is available. At the same time, the air-cooled explosion-proof chiller adopts an explosion-proof design, which can operate safely in flammable and explosive places to ensure production safety.

Techinical Parameters:

| Model | RX- 30AD | RX- 40AD | RX- 50AD | RX- 60AD | RX- 70AD | RX- 80AD | RX- 90AD | RX- 100AD | RX- 110AD | ||

| Cooling capacity | KW/h | 94.8 | 126.4 | 158.0 | 189.6 | 221.2 | 252.8 | 284.4 | 316.0 | 347.6 | |

| TR | 84,000 | 112,000 | 140,000 | 168,000 | 196,000 | 224,000 | 252,000 | 280,000 | 308,000 | ||

| Temperature range | 5℃~35℃(Below 0℃ can be customized) | ||||||||||

| Power supply | 3N-380V/415V 50HZ/60HZ | ||||||||||

| Total power | KW | 24.8 | 33.7 | 41.5 | 45.2 | 57.4 | 62 | 69 | 72.5 | 83.6 | |

| Running current | A | 41 | 56.5 | 69.6 | 75.9 | 96.5 | 86.7 | 116.2 | 122 | 111.3 | |

| Chilled water | m³/h | 15 | 19.6 | 24.2 | 29 | 35 | 40 | 45 | 50.2 | 53.8 | |

| compressor | type | Semi-hermetic screw type | |||||||||

| Start method | Y-△ | ||||||||||

| capacity adjustment | 0,25,50,75,100 | ||||||||||

| input power | KW | 23.3 | 30.7 | 38.5 | 42.2 | 51.4 | 56 | 63 | 66.3 | 73 | |

| Frozen oil | type | HBR-A01 | |||||||||

| filling volume | L | 7 | 7 | 8 | 12 | 16 | 16 | 16 | 16 | 18 | |

| refrigerant | type | R-22/R407C | |||||||||

| control method | Temperature Sensing External Pressure Equalizing Expansion Valve | ||||||||||

| Evaporator | filling volume | KG | 16 | 22 | 27 | 32 | 36 | 42 | 46 | 52 | 56 |

| type | shell and tube | ||||||||||

| condenser | Diameter | mm | DN65 | DN80 | DN80 | DN80 | DN80 | DN100 | DN100 | DN100 | DN125 |

| type | High-efficiency copper-sleeved aluminum-fin type + low-noise external rotor fan | ||||||||||

| Cooling air volume | m³/h | 28000 | 36000 | 45000 | 5500 | 63000 | 74000 | 83000 | 92000 | 102000 | |

| protective device | High and low voltage switch, antifreeze protection, soluble plug, safety valve, overload protection device, coil overheat protector, automatic temperature protection switch, etc. | ||||||||||

| Dimensions | L | mm | 2200 | 2300 | 2500 | 2800 | 2800 | 2910 | 3100 | 3150 | 3150 |

| W | mm | 1100 | 1100 | 1200 | 1200 | 1800 | 2050 | 2050 | 2050 | 2050 | |

| H | mm | 1820 | 2030 | 2030 | 2030 | 2100 | 2100 | 2100 | 2100 | 2100 | |

| weight | KG | 920 | 1120 | 1350 | 1560 | 1780 | 1920 | 2230 | 2450 | 2720 | |

Application Industry:

The air-cooled explosion-proof chiller is mainly suitable for places requiring explosion-proof measures, such as chemical industry, petroleum, natural gas, medicine and other fields. The specific scope of application is as follows:

1.Chemical industry: Inflammable and explosive chemical substances are often involved in chemical production, so it is necessary to use explosion-proof chillers for cooling to ensure production safety.

2.Oil and natural gas: In the process of oil and natural gas extraction, flammable and explosive gases are often involved, so explosion-proof chillers are required for cooling to ensure production safety.

3.Medicine: Inflammable and explosive chemicals are often involved in pharmaceutical production, so explosion-proof chillers are required for cooling to ensure production safety.

Automotive Manufacturing Chemical Engineering Electronics Industry

Electroplating Industry

Injection Molding Industry Pharmaceutical Industry Plastic Packaging Industry Printing Industry

Maintenance Method:

The air-cooled explosion-proof chiller is an important refrigeration equipment. In order to ensure its normal operation and prolong its service life, regular maintenance is required. The following are the matters needing attention in the maintenance of air-cooled explosion-proof chillers:

1.Regular cleaning: It is necessary to regularly clean the air-cooled explosion-proof chiller, including cleaning the condenser and evaporator and other components, to ensure that its surface is clean and free from dirt or dust, so as to ensure the cooling effect.

2.Clean the filter screen regularly: The filter screen needs to be cleaned regularly to avoid dust and dirt from clogging the filter screen and affecting the cooling effect.

3.Regularly replace the refrigerant: The refrigerant needs to be replaced regularly to ensure its cooling effect.

4.Regular inspection of pipes: Regular inspection of pipes is required to ensure that they are not leaking or damaged, so as to avoid refrigerant leakage and affect cooling effect and safety.

5.Regular inspection of electrical components: Regular inspection of electrical components is required to ensure good electrical connections and normal operation of electrical equipment to avoid safety accidents caused by electrical failures.

6.Regularly check the compressor: It is necessary to check the compressor regularly to ensure its normal operation and avoid safety accidents caused by compressor failure.

7.Regularly check the surrounding environment of the unit: It is necessary to regularly check the surrounding environment of the unit to ensure that there are no sundries or obstacles to avoid affecting the normal operation of the unit.

In short, the maintenance of the air-cooled explosion-proof chiller is very important. It needs regular cleaning, replacement of refrigerant, inspection of pipelines, electrical components and compressors, etc. to ensure its normal operation and safety.

|